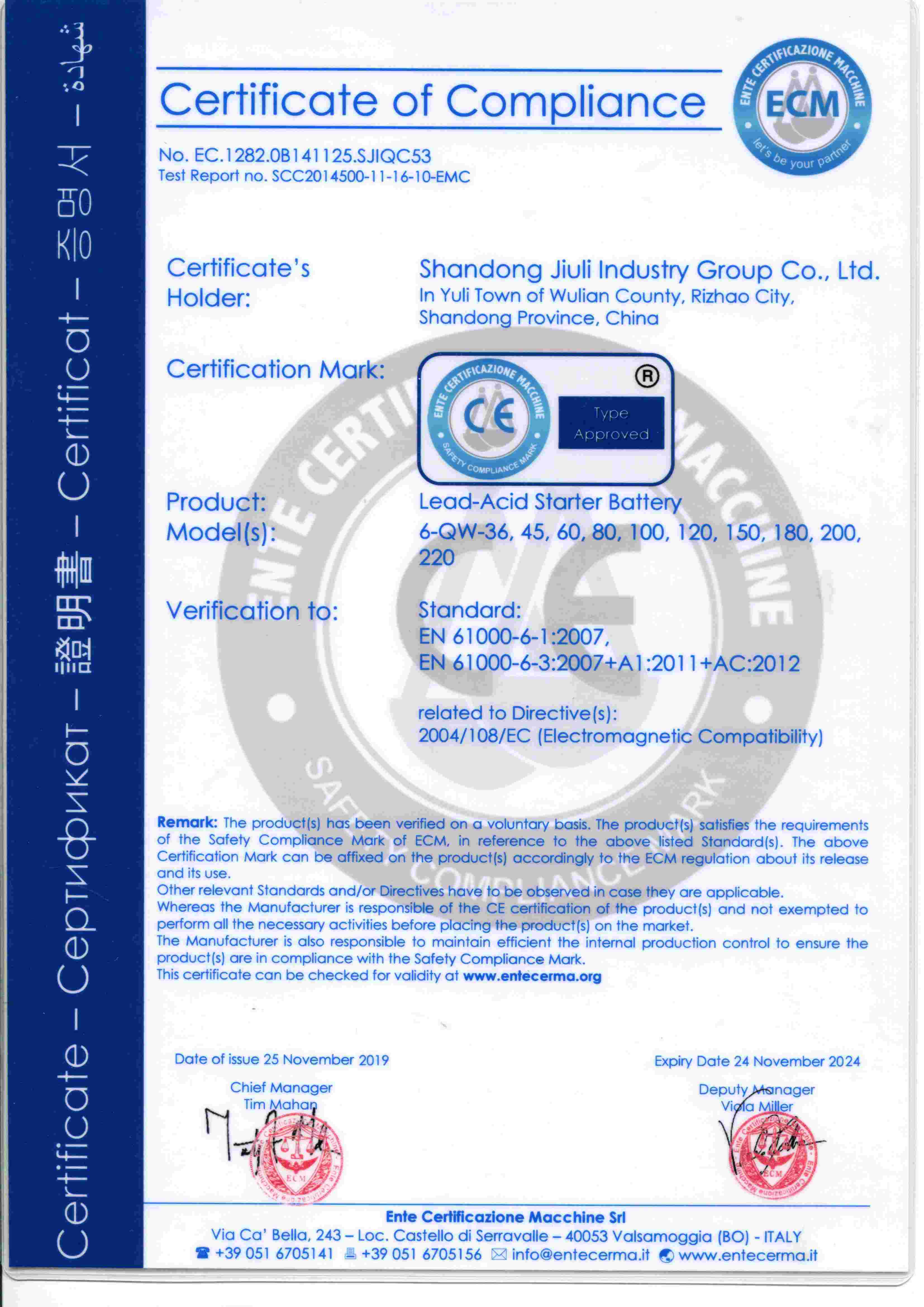

COC

Item specifics

- Period

- 2018/12/22 - 2028/12/22

- Certification bodies

- FDA

Certificate description

Battery Management System Certification: Ensuring Safety, Reliability, and EfficiencyIntroduction:In recent years, the demand for batteries has rapidly increased, driven by the growing adoption of electric vehicles (EVs), renewable energy systems, and portable electronic devices. As the importance of batteries continues to rise, so does the need for robust battery management systems (BMS) that ensure their safe and efficient operation. Battery management system certification plays a crucial role in verifying that these systems meet international standards, ensuring the safety, reliability, and efficiency of battery technologies. This essay will delve into the intricate details of battery management system certification, discussing its significance, the relevant standards, the certification process, and the benefits it offers.1. Significance of Battery Management System Certification:Battery management systems are critical components of battery-based applications. They monitor and control various parameters such as temperature, voltage, current, and state of charge to optimize battery performance, prevent overcharging or over-discharging, and extend battery lifespan. The certification of these systems is essential for several reasons:a) Safety Assurance: Battery safety is paramount, especially considering the potential risks associated with thermal runaway, leakage, or explosion. Certification ensures that BMSs adhere to safety requirements, minimizing the possibility of accidents and hazards.b) Reliability: BMS certification ensures that the system operates reliably under different conditions, such as varying temperatures, loads, and charging profiles. This verification instills confidence in the manufacturers, end-users, and regulatory bodies regarding the system's performance.c) Compliance with Standards: Battery management system certification ensures compliance with relevant international standards, such as ISO26262 for automotive applications, IEC 62619 for stationary energy storage, and UL 1973 for lithium-ion battery modules. Compliance with these standards helps manufacturers gain acceptance meet regulatory requirements, and access global markets.d) Quality Assurance: Certification validates that the BMS meets stringent quality standards, ensuring that it is designed, manufactured, and tested following best practices. This helps prevent product failures, malfunctions, or premature degradation.2. Relevant Standards for Battery Management System Certification:Several internationally recognized standards are applicable to battery management system. These standards define the requirements and guidelines for designing, testing, and operating BMSs. The following are some key standards commonly used in the industry:a) ISO 26262: This standard focuses on functional safety for electrical and electronic systems in road vehicles. It provides guidelines for managing safety risks throughout the development process, including requirements for BMSs used in EVs.b) IEC 62619: This standard addresses secondary cells and batteries containing alkaline or other non-acid electrolytes. It provides specifications for the testing and safety requirements of BMSs used in stationary energy storage systems.c) UL 1973: UL 1973 is a safety standard for lithium-ion battery modules, which include the associated BMSs. This standard covers the construction, electrical aspects, and environmental performance requirements for battery modules and systems.d) UN .3: Although not specific to BMSs, UN 38.3 is an important standard for lithium-ion batteries used in transportation. It defines testing criteria for various aspects, including electrical, thermal, mechanical, and environmental performance.3. Battery Management System Certification Process:The certification process battery management systems involves several steps, including documentation review, assessment of BMS design, and performance testing. The following outlines the typical certification process:a) Documentation Review: The certification body assesses the BMS documentation, including design specifications, schematics, control algorithms, safety measures, and compliance with relevant standards. This review ensures that the manufacturer has followed proper design practices and meets the necessary requirements.b) Design Assessment: The certification body evaluates the BMS's design, including hardware components, software algorithms, communication protocols, and safety features. This assessment verifies the BMS design is suitable for its intended application and provides the required functionalities.c) Performance Testing: Performance testing is a crucial aspect of BMS certification. It involvesing the system to various operating conditions, including temperature cycling, charging/discharging profiles, and fault scenarios. Performance tests assess the BMS's accuracy in monitoring battery parameters, its ability to control charging and discharging processes, and its response to abnormal conditions.d) Compliance Verification: The body verifies compliance with the relevant standards during the testing phase. This includes checking if the BMS meets specific performance requirements, safety regulations, and any other applicable criteria.e) Issuance of Certification: Upon successful completion of the certification process, the certification body issues a certificate indicating that the BMS has met all the necessary requirements. The certification is typically valid for a certain period, after which the BMS may require recertification or periodic audits to ensure continued compliance.4. of Battery Management System Certification:Battery management system certification offers several benefits to manufacturers, end-users, and regulatory bodies:a Enhanced Safety: BMS certification ensures that appropriate safety measures are in place, minimizing the risk of accidents, fires, or explosions caused by battery malfunctions.b) Improved Reliability: Certified BMSs undergo rigorous testing, ensuring their reliability under different operating conditions. This helps prevent unexpected failures, optimizing the performance and lifespan of batteries.c) Market Acceptance: Certification provides manufacturers with a competitive advantage by demonstrating their adherence to international standards. This helps gain trust from customers, investors, and regulatory bodies, enabling access to new markets and business opportunities.d) Regulatory Compliance: Certification helps manufacturers meet legal and regulatory requirements imposed by governmental bodies and industry-specific organizations. Compliance with these requirements ensures smooth market entry and prevents legal and financial implications.e) Customer Assurance: Certified BMSs provide customers with confidence in the safety, reliability, and performance of battery-powered products. This assurance is particularly relevant for applications where failure or malfunction can have severe consequences, such as EVs, medical devices, or aerospace systems.f) Continuous Improvement: The certification process encourages manufacturers to continually improve their BMS designs, manufacturing processes, quality control procedures. This focus on continuous improvement drives innovation, leading to better-performing and more efficient BMSs.Conclusion:Battery management system certification plays a vital role in ensuring the safety, reliability, and efficiency of battery technologies. By complying with relevant international standards and undergoing a rigorous certification process, manufacturers demonstrate their commitment to quality and customer satisfaction. Certified BMSs offer enhanced safety, improved reliability, market acceptance, regulatory compliance, customer assurance, and opportunities for continuous improvement. As the demand for batteries continues to grow, the importance of BMS certification will only increase, ensuring that battery-powered applications meet the highest standards of performance and safety.